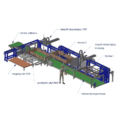

How does CUBO work?

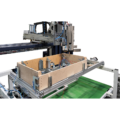

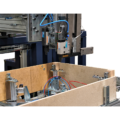

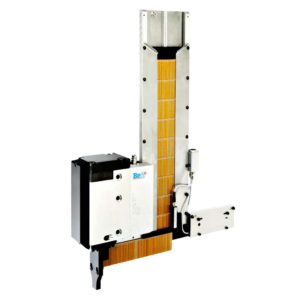

The operator places the box elements in form 1, while in form 2 the body is being nailed together. The process is carried out using an arm equipped with BeA K14 and K380 modular staplers. The finished body is then transferred to a conveyor belt, which moves it to the HDF board assembly zone. At this point, the BeA K380 stapler completes the assembly.

The work is carried out in continuous mode – the operator alternately places the elements in the molds, and the machine automatically carries out subsequent stages of production.

Technical data:

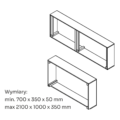

dimensions of manufactured products: 1200 x 671 x 232 mm and 1915 x 640 x 232 mm

equipment: 3 modular staplers 2 x BeA K380 and 1 x BeA K14

multi-axis CNC drives

X, Y, Z axis positioning accuracy: 0.2 mm

touch panel 21″

the ability to remotely monitor the production process

remote service diagnostics

line dimensions: 12100 x 6500 mm