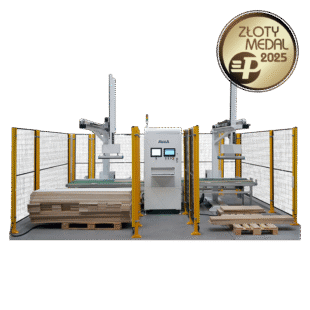

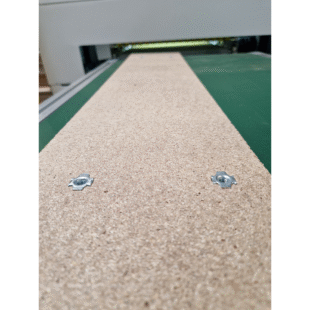

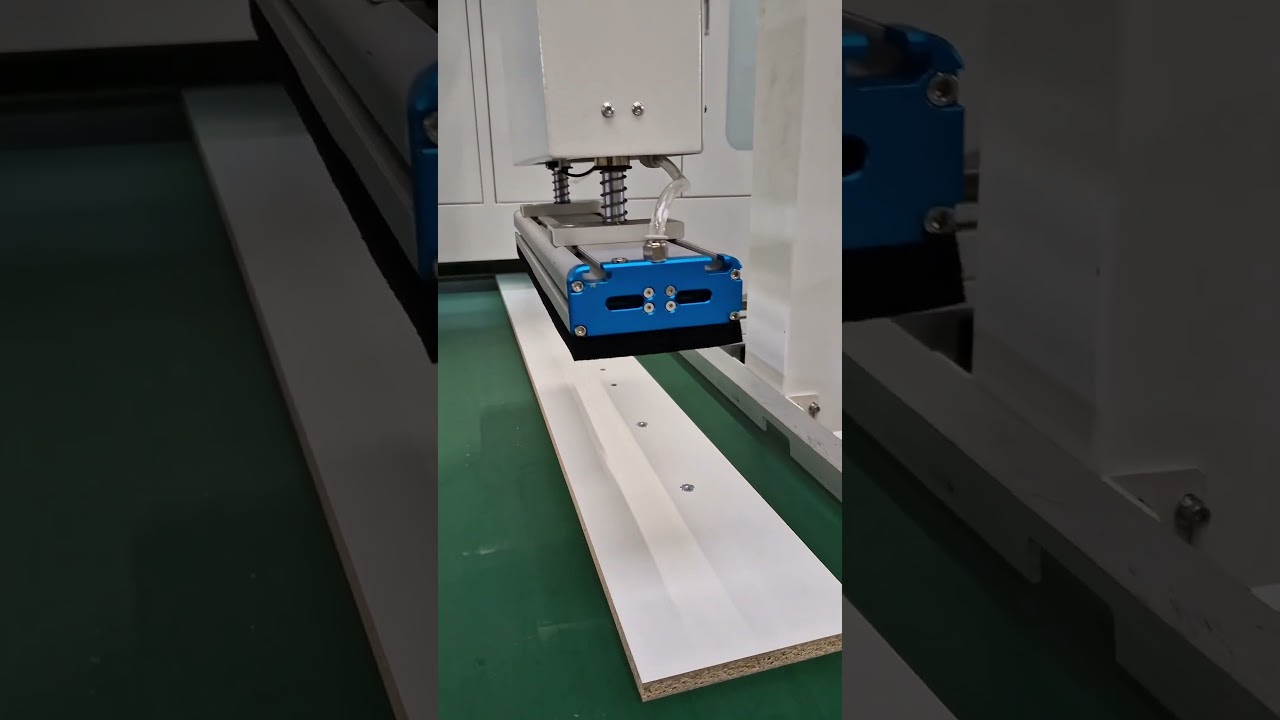

AUTONUT CNC is a fully automatic line for inserting and securing claw nuts in flat elements.

The device independently picks up parts with prepared holes, recognizes their position, inserts and secures the nuts, and then automatically places the finished product on a pallet.

Thanks to integration with CNC machines, the ability to skip selected holes and quiet operation, AUTONUT significantly reduces operation time and improves production quality – increasing the competitive advantage of your plant.

Efficiency and automation:

• Fully automatic process: picking, recognizing, filling, putting away

• Efficiency: 2–5 seconds per cap (depending on spacing)

• Possibility to work on details up to 1000×2200 mm

• Possibility of integration with a CNC machine – direct collection and storage of parts

• Automatic arrangement of finished elements on a pallet

Flexibility and configuration:

• Available versions for workpiece widths up to 400 mm or 1000 mm

• Option to mount 2-axis manipulators (loading and unloading)

• Supports 1 or 2 types of nuts simultaneously

• Vacuum pickup up to 25 kg

• Can be easily integrated into existing production cycles

Precision and control:

• Vision system for hole detection

• HMI with Polish menu – intuitive operation and programming

• Precise control of each cap's feeding

• System preventing the caps from getting stuck in the feeder

• Consistent quality and process repeatability

Safety and comfort of work:

• Compliance with the Machinery Directive – CE marking

• Extensive security system for work zones

• Quiet operation – much lower noise level than traditional solutions

• Better comfort for operators and lower acoustic load on the plant

AUTONUT CNC automation of the process of inserting dog nuts

AUTONUT CNC automation of the process of inserting dog nuts